Enapter AG to deliver containerised electrolysers for Europe’s largest renewable energy research project and Canadian Clean Hydrogen Hub

Karlsruher Institut für Technologie (KIT) orders AEM Electrolyser with a capacity of 500 kW to be integrated in Energy Lab, Europe’s largest research infrastructure for renewable energy. An additional 0.5 MW AEM Electrolyser order Enapter received from a Clean Hydrogen Hub in Canada.

- Karlsruher Institut für Technologie (KIT) orders AEM Electrolyser with a capacity of 500 kW

- To be integrated in Energy Lab, Europe’s largest research infrastructure for renewable energy

- Additional 0.5 MW AEM Electrolyser order from a Clean Hydrogen Hub in Canada

Berlin, June 11, 2024. Enapter AG (ISIN: DE000A255G02) has received an order for an AEM Nexus 500 electrolyser from the prestigious Karlsruher Institut für Technologie (KIT), which has on several occasions been recognised as one of the 100 best universities in the world. This containerised AEM Electrolyser for the production of green hydrogen has a capacity of 500 kW and will be used as part of Europe’s largest research infrastructure project for renewable energies – ‘Energy Lab’ in Karlsruhe, Baden-Württemberg. With this order, Enapter deepens its business relationship with KIT; the university already became a customer of the electrolyser manufacturer in 2020.

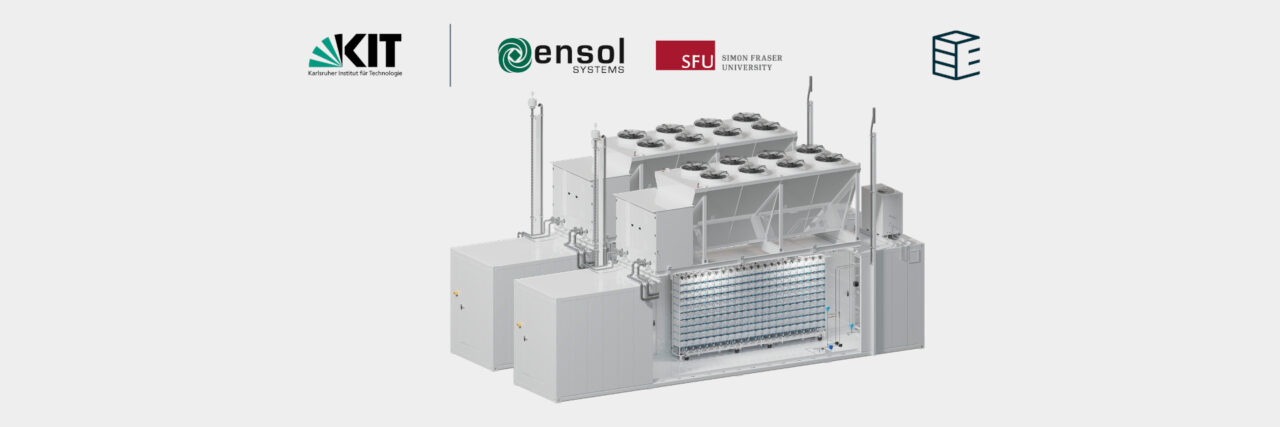

Energy Lab is a KIT project in cooperation with the Helmholtz Centres, the German Aerospace Centre and the Jülich Research Centre. The project is jointly researching the intelligent linking of environmentally friendly energy generation, storage and supply options. In addition, energy systems of the future are simulated and tested there based on real consumer data. The aim is to improve the transport, distribution, utilisation and storage of electricity and thus create the basis for the energy transition. Green hydrogen produced with the AEM Nexus 500 will be used for various test scenarios of sector cogeneration, including waste heat projects, and will supply several pilot plants. The AEM Nexus 500 combines several dozen AEM electrolysis Stacks to form a complete system that can produce around 225 kilograms of hydrogen per day, with a hydrogen purity of 99.999%. The Energy Lab is funded by the Federal Ministry of Education and Research (BMBF), the Federal Ministry for Economic Affairs and Energy (BMWi) and the Baden-Württemberg Ministry of Science, Research and the Arts (MWK).

Enapter has received another order for an AEM Nexus 500 from Canada. Simon Fraser University (SFU) in Burnaby, British Columbia, will deploy the AEM Nexus 500 as part of the “Clean Hydrogen Hub” research project. The hydrogen produced on site will be made available for industrial companies and researchers to use. Additionally, the project aims to raise public awareness about hydrogen, inform on its potential and structures, and reduce greenhouse gas emissions in British Columbia through hydrogen utilization. Enapter's integration partner, Ensol Systems, is responsible for the project implementation. The commissioning of the AEM Nexus 500 at SFU is scheduled for the fourth quarter of 2025. The Clean Hydrogen Hub research project is supported with CAD 10 million by the Pacific Economic Development Agency of Canada, a federal economic development agency for British Columbia under the Canadian government. Ensol had previously ordered single-core class electrolysers from Enapter and, after successful practical testing, is now extending their use to the multi-core class as well.

Jürgen Laakmann, Enapter CEO: “Our electrolysers meet the highest quality standards and fulfil the diverse requirements of our customers worldwide. This is the reason why existing customers are now increasingly ordering large devices in the megawatt range after their initial experience with our compact EL-class single-core devices: Our AEM Electrolyser technology has already proven its advantages in practice.”

About ENAPTER

Enapter is an innovative energy technology company that manufactures highly efficient hydrogen generators – known as electrolysers – to replace fossil fuels and thus drive the global energy transition. Their patented and proven Anion Exchange Membrane (AEM) technology enables the series and mass production of cost-effective plug-&-play electrolysers for green hydrogen production at any scale and any place. Their modular systems are already used by more than 340 customers in 50+ countries, in the energy, mobility, industrial, heating and telecommunications sectors. Enapter has its main office in Germany as well as an R&D and production site in Italy. Enapter AG is listed on the regulated market of the Frankfurt and Hamburg stock exchanges, WKN: A255G0, ISIN: DE000A255G02.

Further information:

Website: https://www.enapter.com

Twitter: https://twitter.com/Enapter

LinkedIn: https://www.linkedin.com/company/enapter

Facebook: https://www.facebook.com/enapterenergystorage

Instagram: https://www.instagram.com/enapter/

General press contact:

Enapter Public Relations

Tel.: +49 (0) 30 921 008 130

E-Mail: pr@enapter.com

Financial press contact:

Ralf Droz / Doron Kaufmann

edicto GmbH

Tel.: +49 (0) 69 90 55 05-54

E-Mail: enapter@edicto.de