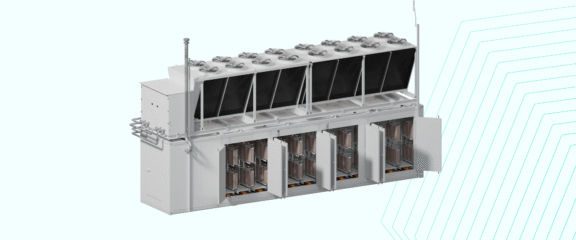

Enapter AG expands product portfolio with new multicore electrolyzer Nexus 2500

See more

News Round-Up – Innovation, Recognition & Partnerships Driving the Hydrogen Transition

See more

Interview with Jan-Justus Schmidt, Co-Founder Enapter and Board Member Wolong Enapter JV

See more

Enapter AG expands product range and increases efficiency of hydrogen production by using batteries as an additional component

See more

Enapter AG: Continued strong demand for AEM electrolyzers in the megawatt range from Italy – New orders in the millions

See more