AEM di Enapter

Siamo i pionieri e i leader di mercato degli elettrolizzatori AEM commercializzati e all’avanguardia nella ricerca e sviluppo dell’elettrolisi AEM.

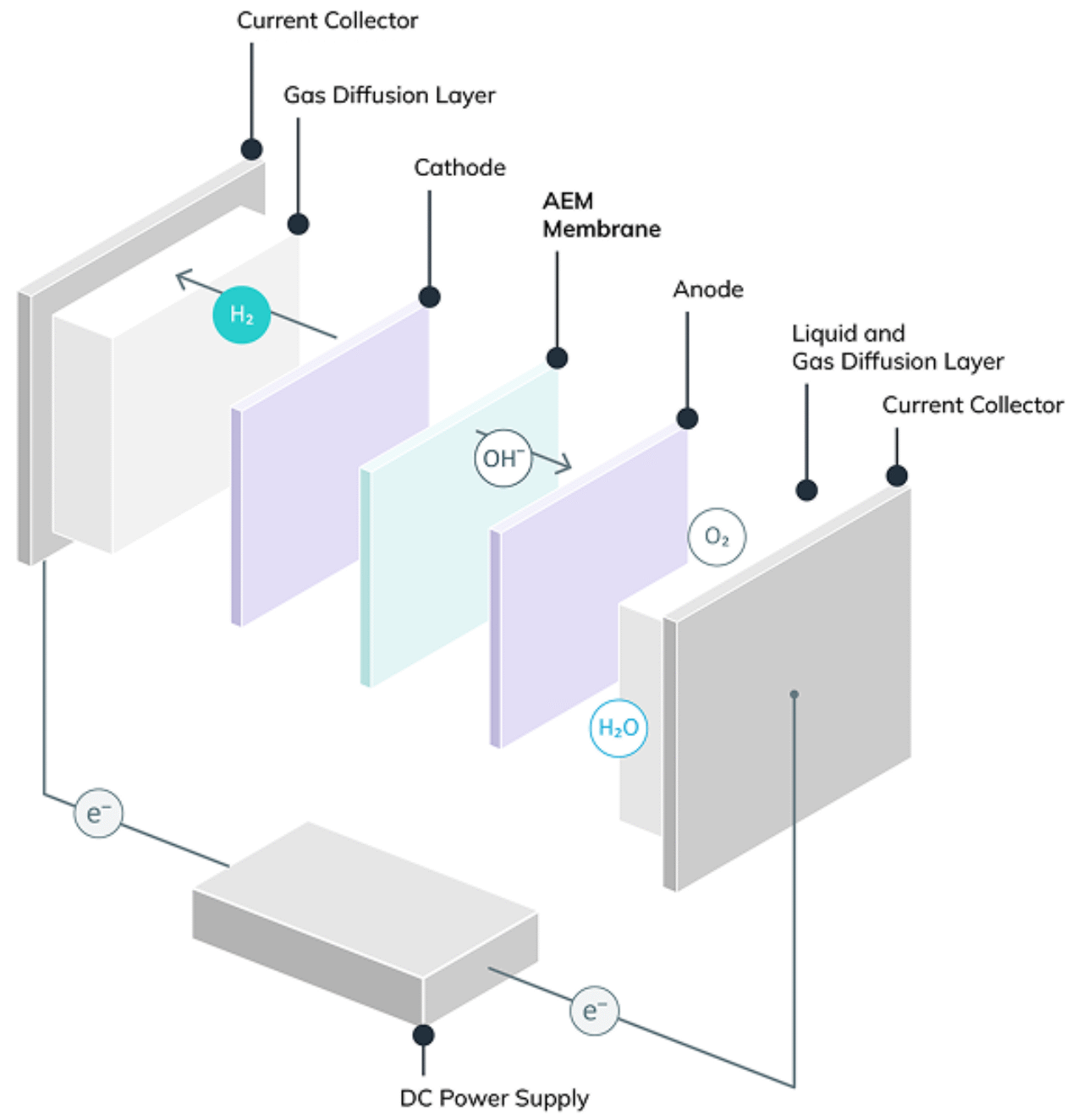

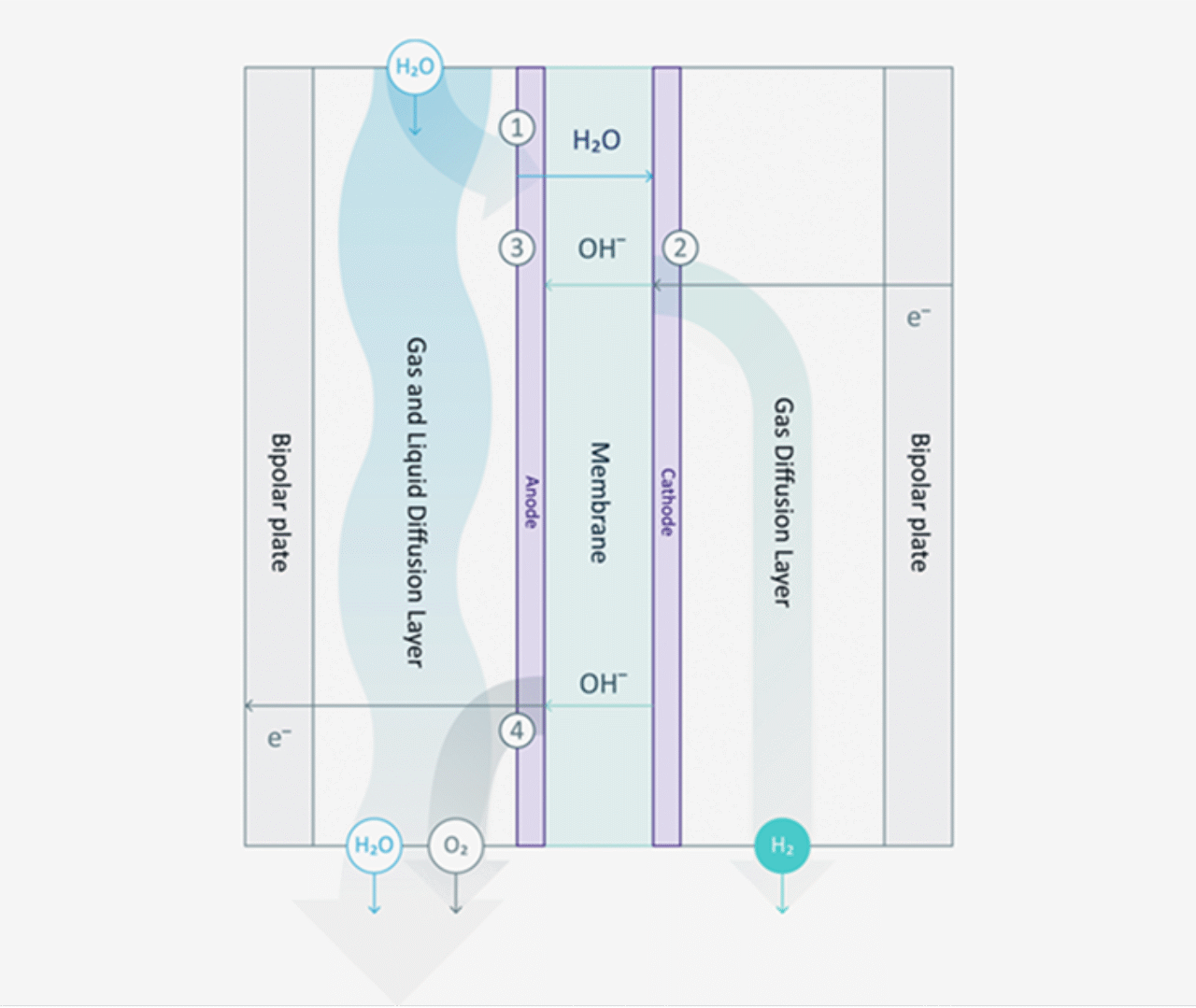

L’elettrolisi AEM (Anion Exchange Membrane) è un tipo di tecnologia di elettrolisi dell’acqua utilizzata per produrre idrogeno. A differenza dell’elettrolisi a membrana a scambio protonico (PEM), l’elettrolisi AEM impiega una membrana semipermeabile a scambio anionico che conduce ioni a carica negativa (anioni) per scindere le molecole d’acqua in idrogeno e ossigeno.

Uno dei principali vantaggi dell’elettrolisi AEM: Non richiede catalizzatori di metalli nobili ad alto costo. Al contrario, può utilizzare catalizzatori di metalli di transizione a basso costo. Analogamente all’elettrolisi dell’acqua alcalina, gli elettrodi dell’elettrolisi AEM operano in un ambiente alcalino. Tuttavia, rispetto alla PEM, i requisiti dell’acqua per l’elettrolisi AEM sono meno severi e si può utilizzare una soluzione leggermente alcalina, riducendo il rischio di perdite e i problemi di gestione associati alle soluzioni altamente alcaline.

Grazie a questo processo, gli elettrolizzatori AEM di Enapter producono idrogeno verde con una purezza del 99,9% (fino al 99,999% con un essiccatore) a una pressione di 35 bar, utilizzando solo acqua ed elettricità rinnovabile.

Tecnologia AEM a confronto

A differenza degli elettrolizzatori PEM, gli elettrolizzatori AEM non necessitano di protezione contro la corrosione del titanio né del costoso iridio. La nostra produzione standardizzata consente inoltre di ottenere notevoli vantaggi in termini di costi. Inoltre, evitano gli svantaggi della tecnologia alcalina: soprattutto, la minore capacità di far fronte alle variazioni di carico e alle dinamiche delle energie rinnovabili intermittenti.

La nostra tecnologia AEM combina il meglio degli elettrolizzatori PEM e alcalini.

_Benefici

Elevata flessibilità operativa

La sua gamma di produzione di idrogeno si adatta alle fluttuazioni energetiche delle fonti di energia elettrica rinnovabili.

Tempo di risposta rapido

Rapido aumento/riduzione in risposta a questi cambiamenti nel carico energetico derivante dalle fonti rinnovabili intermittenti.

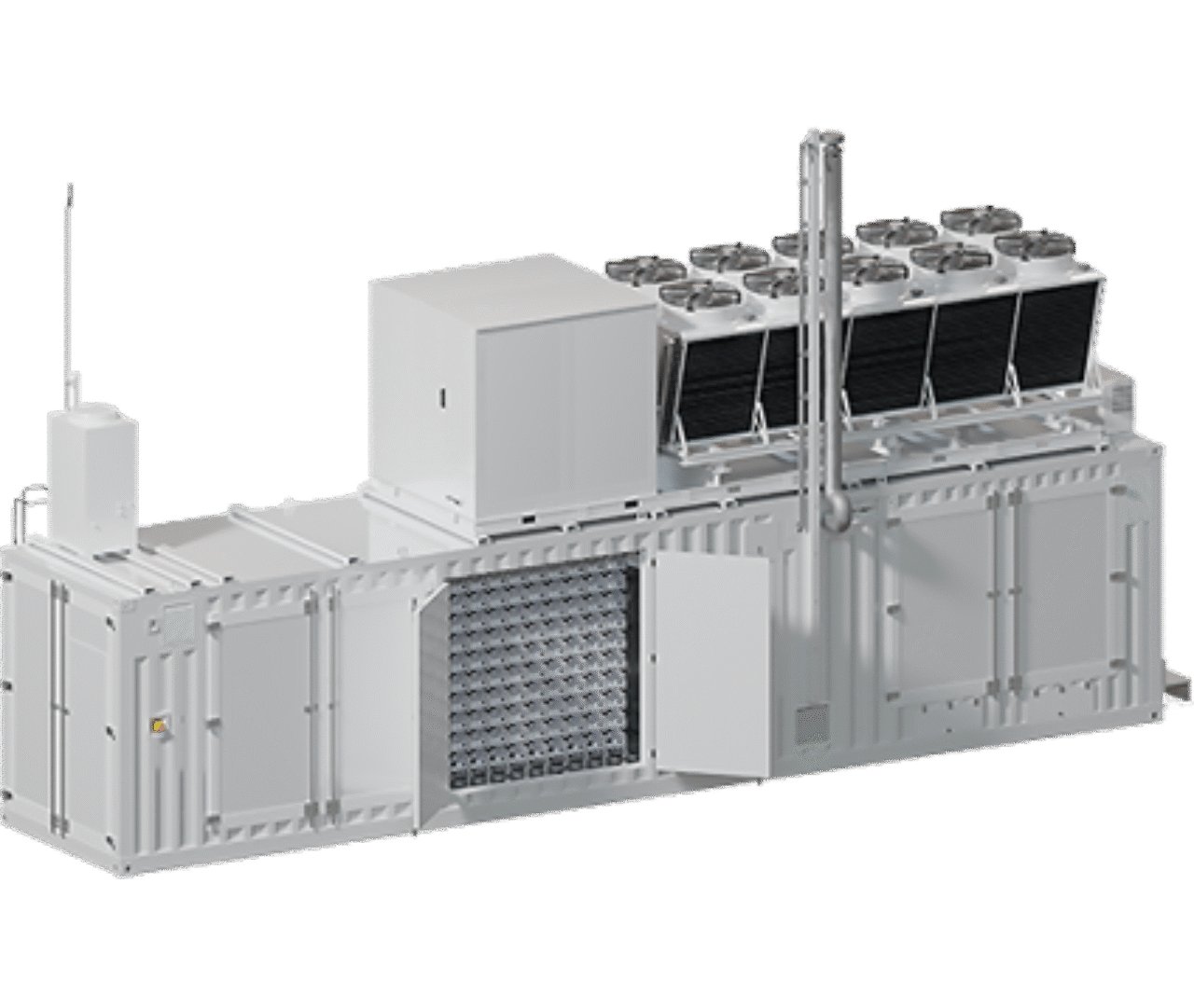

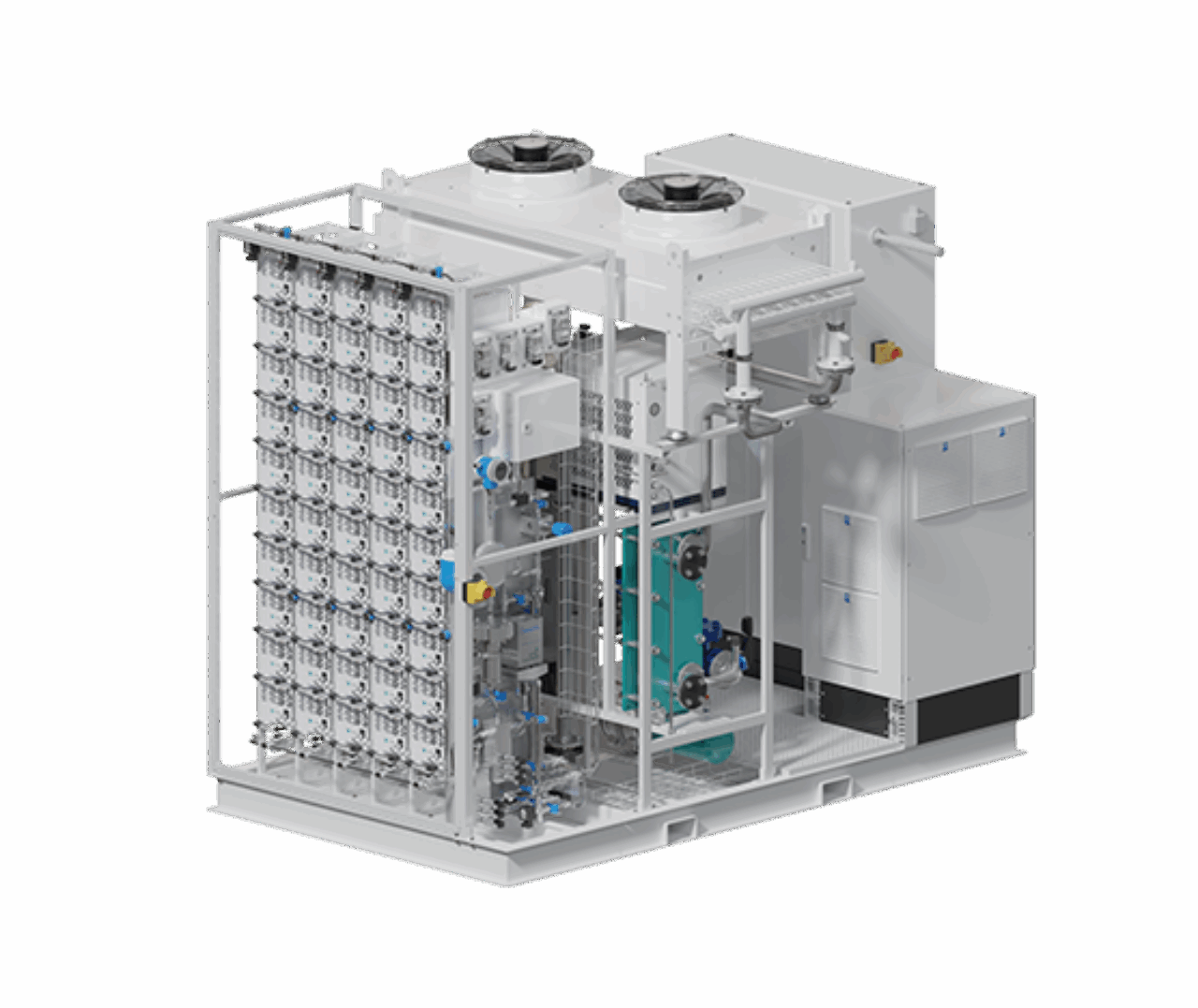

Ingombro ridotto

Sistemi modulari compatti e dal design intelligente consentono la produzione di H2 esattamente nella quantità necessaria.

Stabilità dei prezzi

La tecnologia AEM evita l’uso di materie prime costose come l’iridio, favorendo la stabilità dei prezzi e della catena di approvvigionamento.

A prova di futuro

Le membrane AEM e gli ionomeri/le leganti non richiedono l’uso di materiali PFAS non degradabili, consentendo all’AEM di conformarsi alle imminenti restrizioni PFAS.

_Scopri l’esperienza di Enapter

La tecnologia degli elettrolizzatori AEM è stata sviluppata per la prima volta dall’azienda italiana di ricerca e sviluppo ACTA S.p.A nel 2009, prima che Enapter ne acquisisse la tecnologia di base, i brevetti e il team di elettrochimica nel 2017.

In qualità di leader mondiale nello sviluppo e nella produzione di elettrolizzatori AEM, Enapter vanta oltre 20 anni di esperienza nel settore e un solido team di ricerca e sviluppo che continua a migliorare la tecnologia AEM.

Come funziona l'elettrolisi AEM?

Scopri i meccanismi dell’elettrolisi AEM nel nostro articolo dettagliato sul blog. (Inglese)

Microscopio Elettronico a Scansione (SEM)

Scopri come superiamo i limiti della ricerca e sviluppo con il nostro microscopio elettronico a scansione (SEM). (Inglese)

Produzione decentralizzata di idrogeno verde

I concetti decentralizzati di H2 che producono idrogeno verde da energie rinnovabili assumeranno un’importanza sempre maggiore. Come si inseriscono gli elettrolizzatori AEM in questo studio pubblicato dall’Agenzia tedesca per l’energia dena? (in inglese)

Iridio e l'economia dell'idrogeno verde

Scopri come un aumento della domanda di iridio potrebbe causare carenze di approvvigionamento e costi più elevati, rallentando potenzialmente la transizione verso l’idrogeno verde. (in inglese)

Enapter Handbook

Consulta il nostro Handbook e scopri la nostra vasta base di conoscenze sulla tecnologia AEM, l’idrogeno verde e tutti i dettagli tecnici sui nostri prodotti.