_Challenges and Opportunities in the Energy Landscape

Power-to-X technologies are key to decarbonizing sectors where direct electrification isn’t feasible — from aviation to chemical production. Central to these technologies is green hydrogen, enabling the production of sustainable fuels and carbon-neutral commodities like e-fuels, green methanol, and green ammonia.

Yet the transition away from grey and blue hydrogen remains urgent. Fossil-based hydrogen solutions continue to emit substantial CO₂ and undermine climate goals. Compounding the challenge, Power-to-X operations require unwavering reliability — any disruption or downtime can lead to significant financial losses due to the complex and time-consuming nature of restarting production.

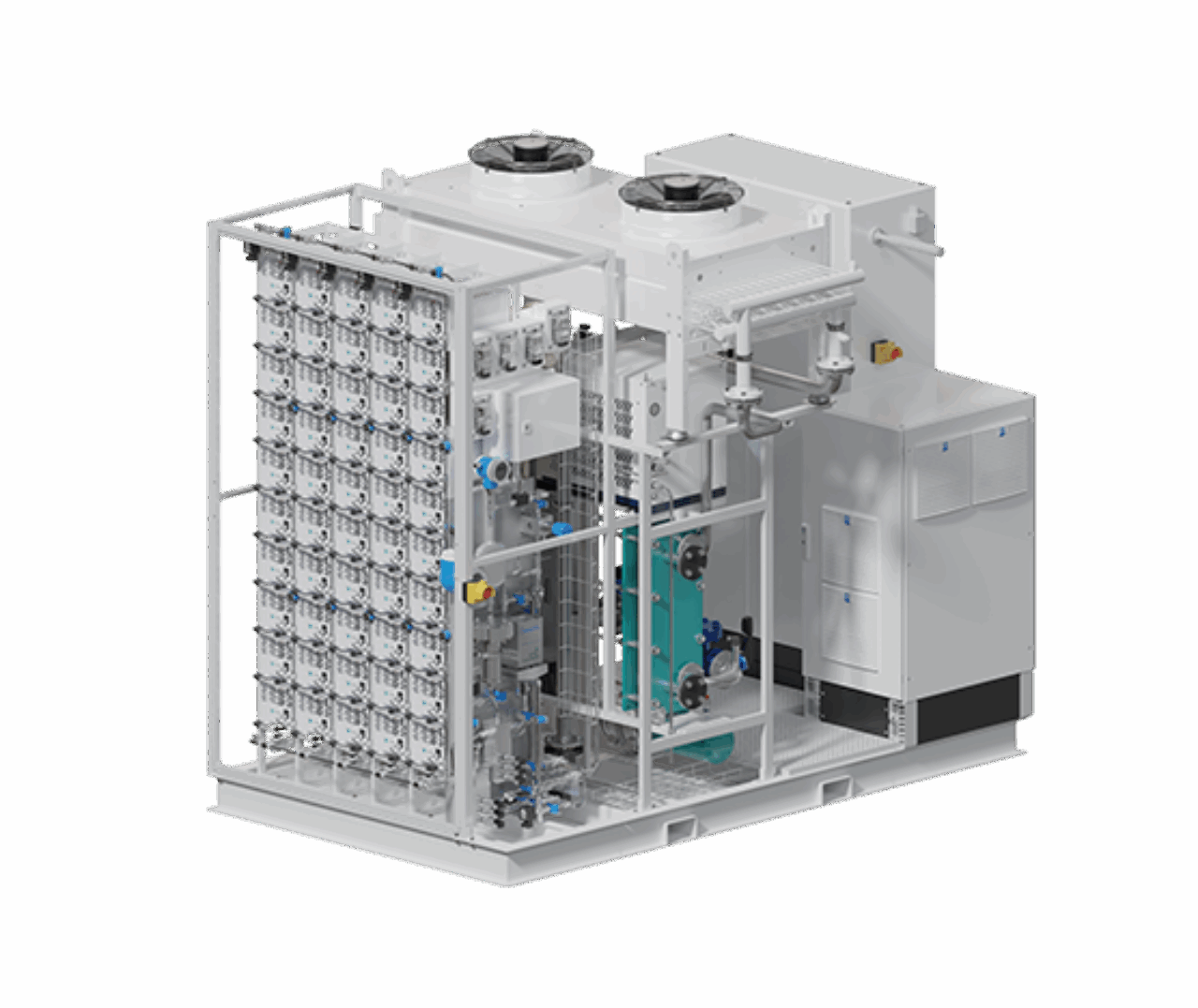

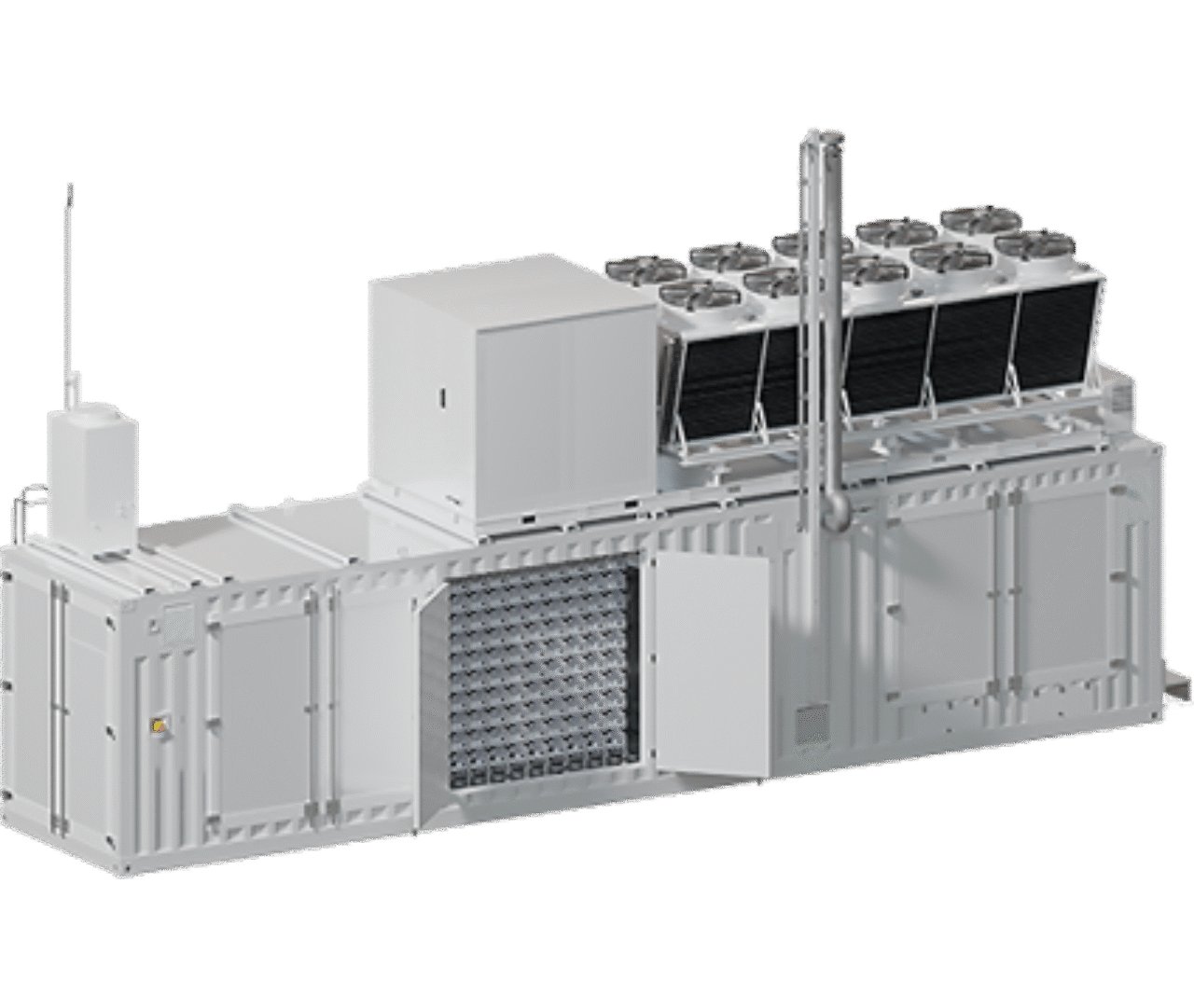

This is where green hydrogen becomes more than a climate solution — it’s a resilience strategy. And with Enapter’s AEM technology, it becomes both feasible and future-ready.