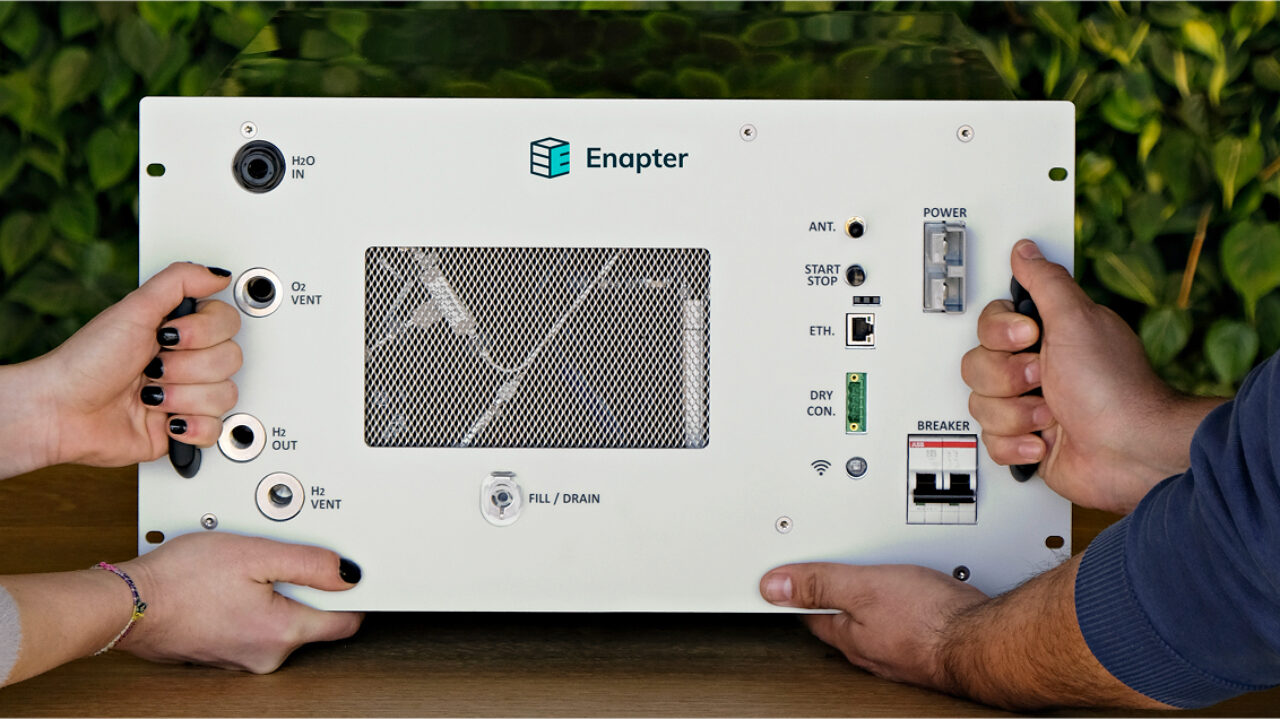

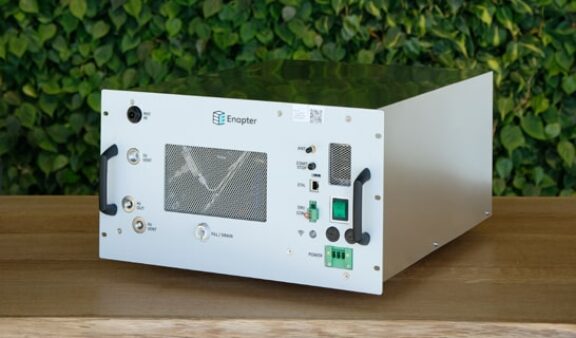

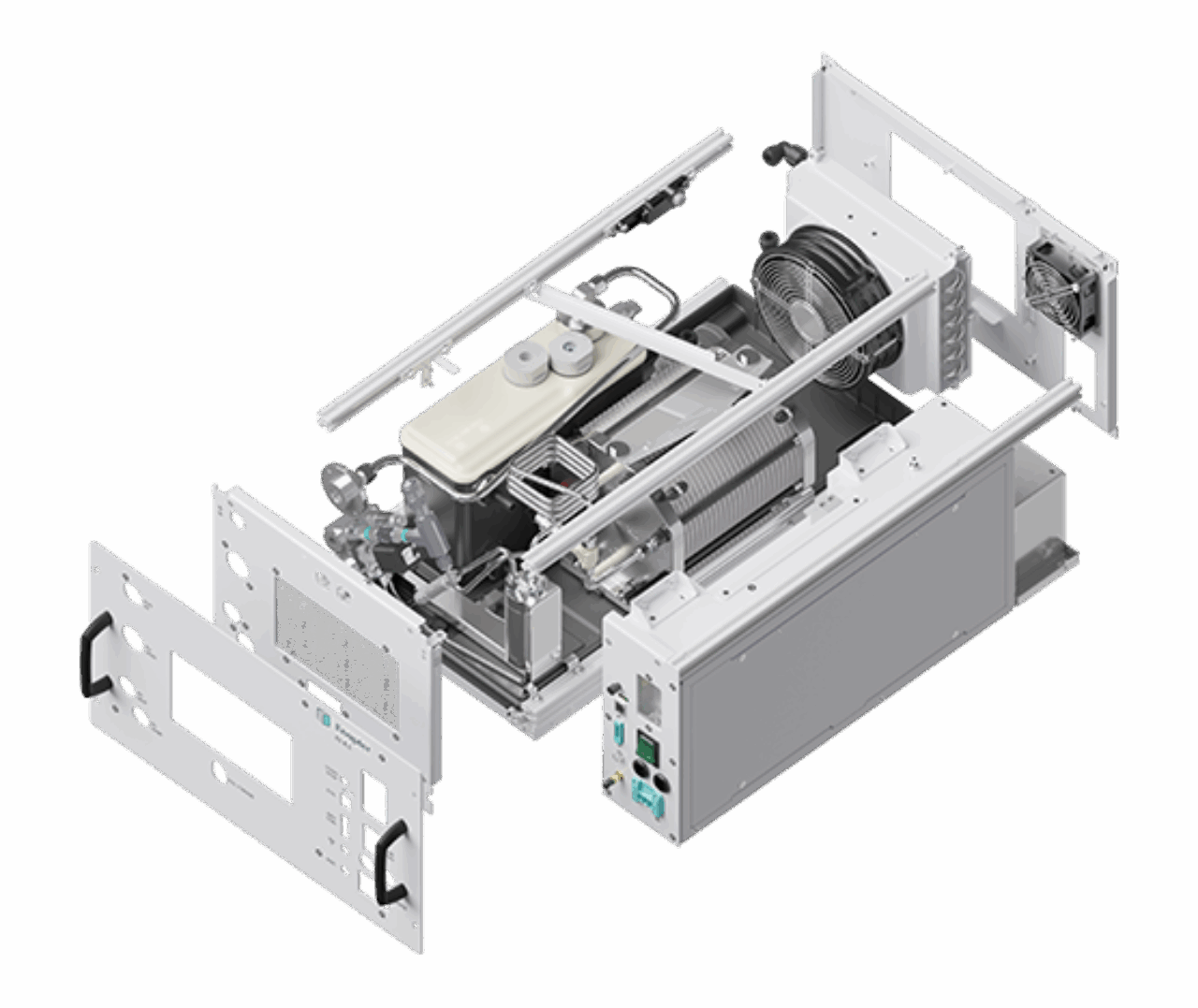

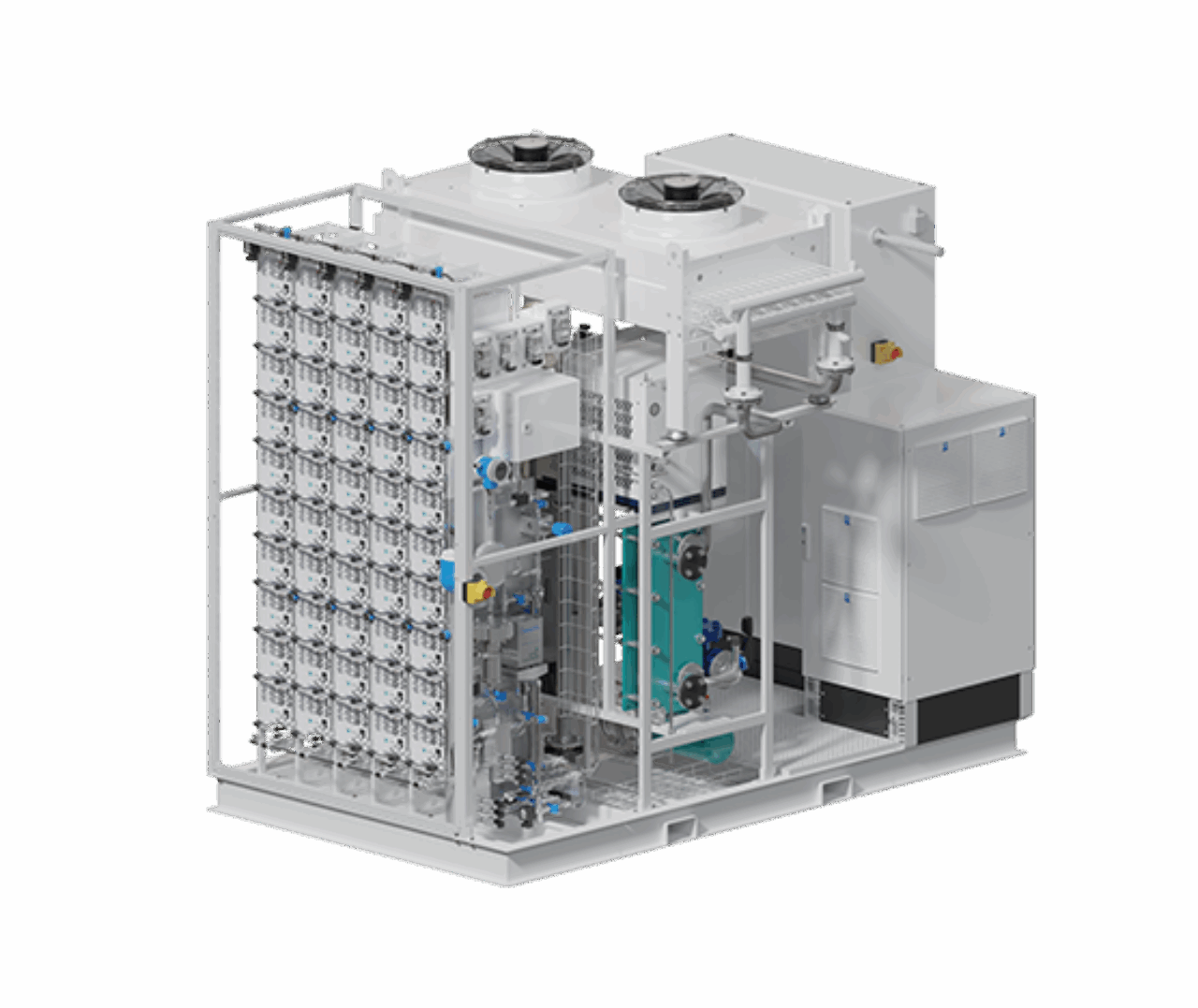

_AEM Electrolyzer EL 4

With over 7,500 units deployed worldwide, our single-core electrolyzers enable the swift start of your green hydrogen journey.

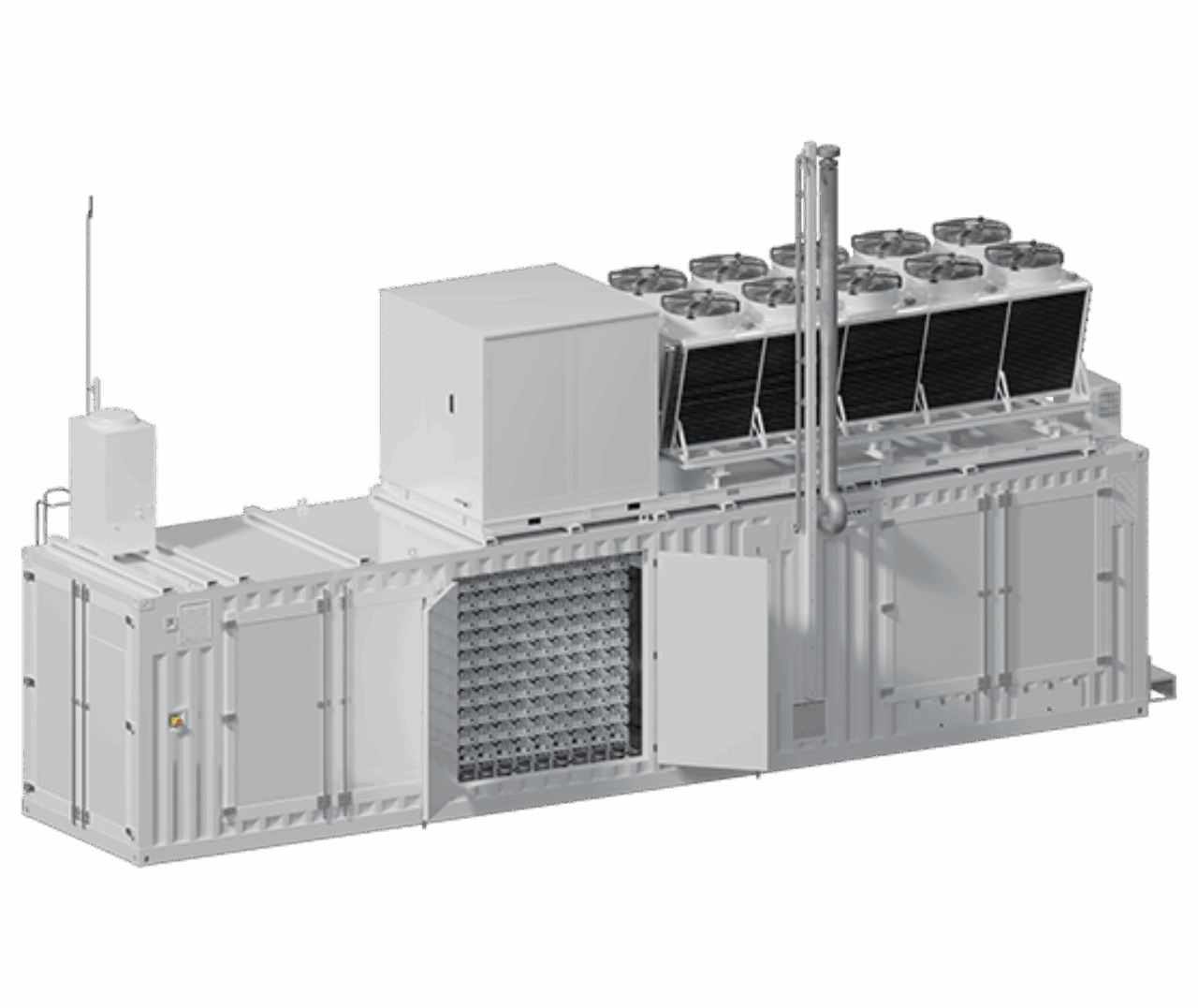

Whether replacing grey H2, creating new applications or installing long-term energy storage, our patented AEM technology scales up as you do: Take single electrolyzers to pilot your solutions and easily expand with extra modules for greater green hydrogen capacity.