Building Hydrogen Futures

To make all of this happen, we act with urgency, opt for simplicity and insist on transparency.

_Enapter at a glance

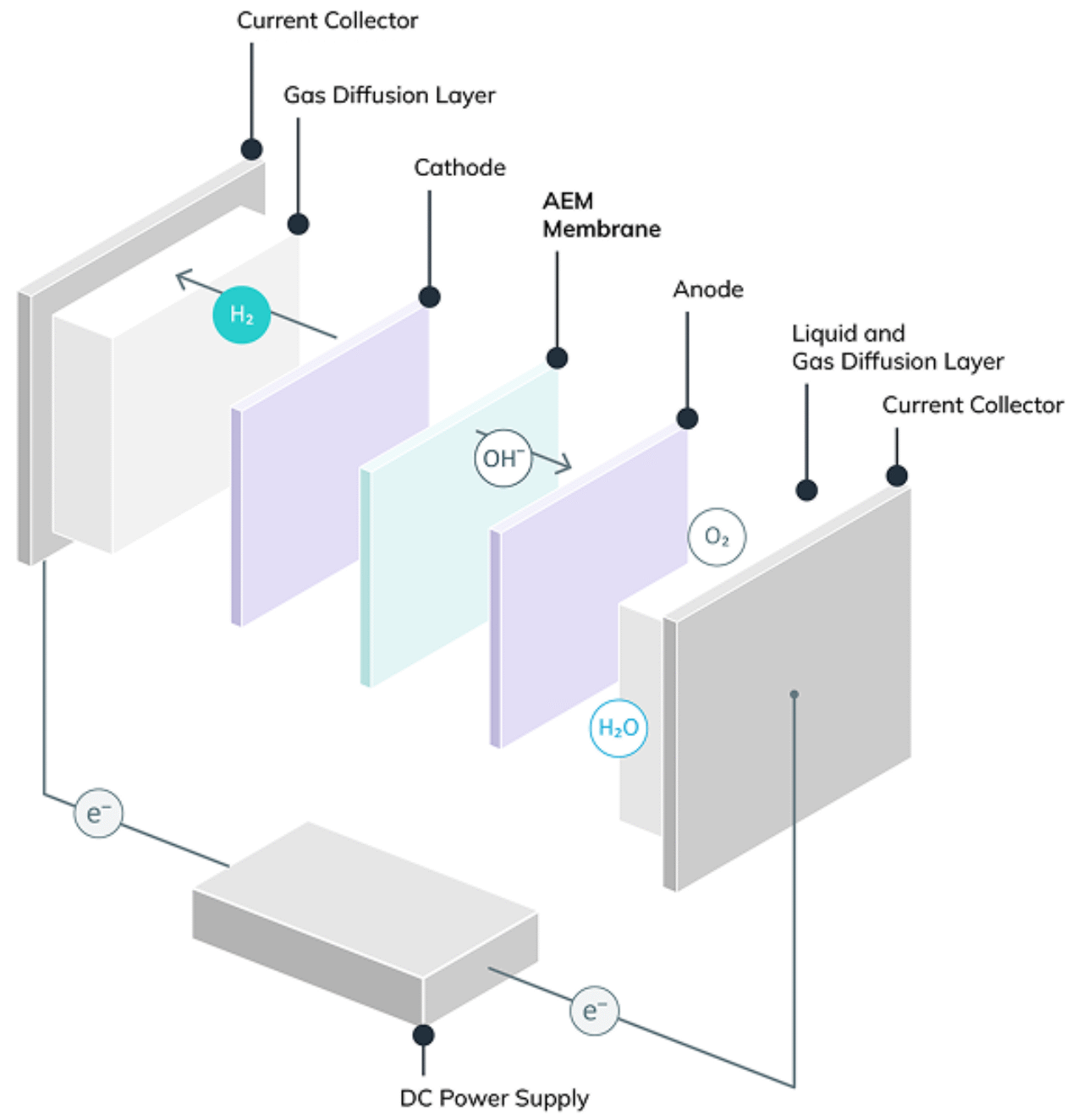

_AEM Technology

Our core technology is the patented Anion Exchange Membrane (AEM) Electrolyzer.

We are the pioneers and market leader of commercialized AEM Electrolyzers and at the forefront of R&D for AEM Electrolysis.

_What sets us apart

Our Vision

To live in a world where fossil fuels are no longer used and green hydrogen fuels and powers the world via renewable energy sources.

Our Mission

To make green hydrogen affordable and accessible to all. We are reducing the cost of water electrolysis so hydrogen is competitive with fossil fuels.

Our Objective

To be responsible for 10% of global hydrogen generation capacity by 2050. We work towards the overall goals set by the Hydrogen Council.

_What we stand for

Urgency

Enapter only exists because we want to play a significant part in tackling climate change; leveraging the power of AEM electrolysers to help do this was the sole reason this company was founded.

Simplicity

We develop simple, modular and standardised electrolyser units that can be mass-produced and stacked to provide as little or as much green hydrogen as needed, anywhere, anytime. One with plug-and-play capability and integrated software to make things as easy as possible.

Transparency

People know exactly what to expect in working with Enapter, what it will cost and how it can help them achieve their clean power and energy independence goals. At the same time they know that we don’t provide hardware customisation — but that our partners stand ready to help integrate our hydrogen systems.

_Our management team

Dr. Jürgen Laakmann

CEO- 20+ years of management experience in strategy consulting, automotive and tech

- Extensive experience in Private Equity and M&A

- Previously CEO at Formel D Gruppe, responsible for opening 20+ international offices and daughter companies

Gerrit Kaufhold

CFO- Part of Enapter’s growth since the reverse-merger in 2020

- Previously tax advisor and auditor for a Big-Four accounting company

- Managing partner of an auditing company for many years

Ivan Gruber

CTO- Responsible for Operations, Engineering and R&D

- 15+ years of management experience in hydrogen, automotive, tech and strategy consulting

- Extensive experience in managing multi-site engineering teams & operations

Our Story

To find the origins of Enapter, we have to flash back to the jungle-clad hills of Chiang Mai, Thailand. The German software CEO Sebastian-Justus Schmidt had moved there to be closer to clients in 2004, also the year the Italian firm ACTA was founded, focusing on R&D in fuel cell and AEM electrolysis. Years later, several of their AEM Electrolyser prototypes went to the Schmidt family’s sustainable microgrid residence – the Phi Suea House.

Our Partners

Are you looking for an integrator to bring your hydrogen project to life? Since Enapter focuses solely on manufacturing game-changing electrolyzers, our network of professional Certified Partners is there to help you effortlessly integrate your hydrogen solution.

Our Leadership team

Our leadership team is driven by a shared passion for sustainable energy, with a wealth of expertise in innovation, technology, and business. Together, they are guiding Enapter towards a greener future with cutting-edge hydrogen solutions.